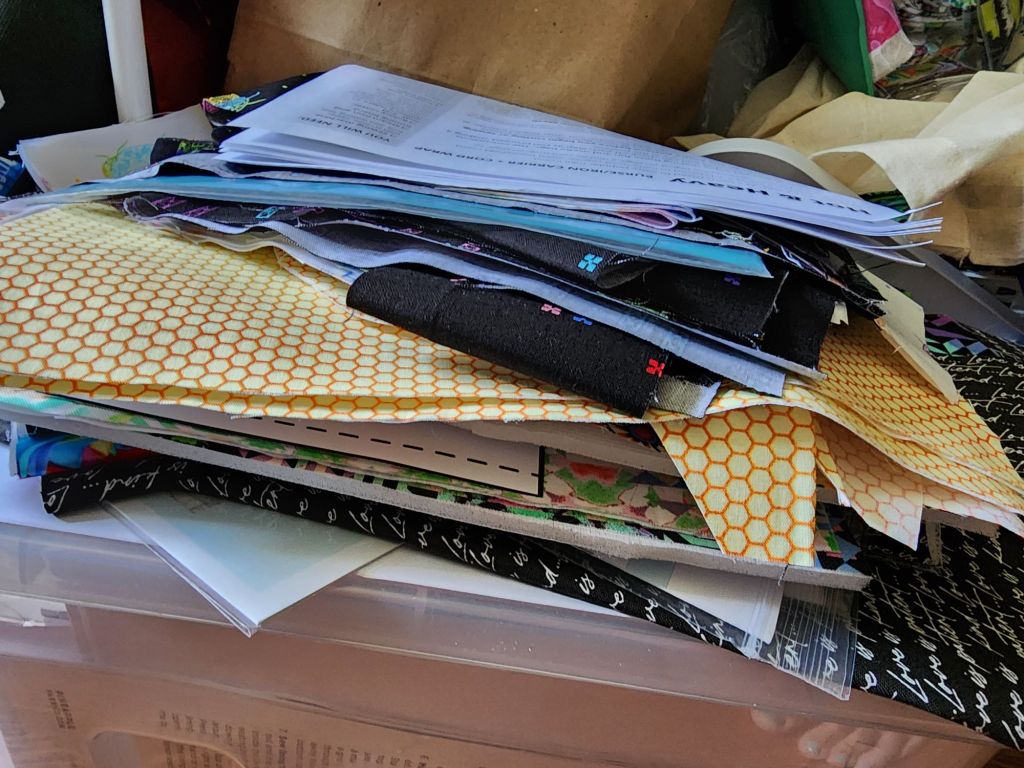

After cutting the fabric in the project pile, my next task is to cut and fuse the interfacing. I find that it is much more efficient to do this almost assembly-line style since I can just pull out bolts of SF101 (Shape Flex by Pellon), Flex Foam (2 side fusible), Fusible Fleece, and Peltex and just get to work.

And yes, I do buy my interfacing by the bolt and I try to keep a back-up bolt of each in the garage with my main fabric stash. I wait for the good sales, and usually can get good deals online from Joann’s. I also, keep ANY potential usable scraps. They come in handy for days like this.

Don’t you just love all of these bright prints! They are so fun and happy to work with – as is my mini Oliso iron. I got this iron before Oliso irons were “cool” and I still can’t believe I scored it for around $30 on Amazon a few years ago.

As I finish prepping each project, I make sure to keep everything together except the pieces that will need to be quilted. I stacked those up together, so when I set up my machine to quilt later today, I can just do all the quilting in one session.

Once I have the pieces that need quilting completed, then I will decide on a sewing order. I like to set it up so I can keep the same thread in the machine from one project to the next as long as possible. I also like to start with a couple of quick projects before diving into something more complicated.

There is just something so satisfying about spraying the Best Press, ironing on the interfacing, and getting the patterns and fabric all organized!